LIFE GIFT VIETNAM INVESTMENT MANUFACTURING CO., LTD

LIFE GIFT VIETNAM INVESTMENT MANUFACTURING CO., LTD is proud to be one of the health food manufacturers in Vietnam that has been granted GMP certificate by the Food Safety Department – Ministry of Health – Quality Management System ISO 22000:2018.

LIFE GIFT VIETNAM’s production activities are currently focusing on 5 forms as follows: production lines for products in the form of granules, powders, tablets, film-coated tablets, sugar-coated tablets, hard capsules, hard capsules, soft pellets…

With the mission of improving the health and quality of life for consumers, Life Gift Vietnam is constantly promoting its advantages of financial capacity, modern production lines, and highly qualified personnel from the University. or more, coordinate with domestic and foreign experts to diversify products and services, increase value and efficiency of production and business in the integration period. Since then, Life Gift Vietnam hopes to be able to accompany the community and consumers. Promises to bring absolute peace of mind so that domestic and foreign consumers can enjoy life to the fullest.

With the goal of creating product lines of good quality, safety and convenience. At the beginning of 2019, Life Gift Vietnam Investment and Production Co., Ltd. started construction of Life Gift Vietnam Factory with a total investment of 2 million USD.

The factory was built according to the standard: “GMP Good Manufacturing Practices – ISO 22000:2018 and completed in January 2020 including workshops, storage warehouses, laboratories and office areas.

As of June 2020, Life Gift Vietnam factory is proud to be one of 140 factories nationwide that have been granted GMP certification by the Ministry of Health.

VISION

Life Gift is an authority in researching, developing, and manufacturing high-quality healthcare products that meet international standards. Our goal is to establish ourselves as a reliable partner, providing optimal health solutions through the use of natural medicinal resources and cutting-edge technology.

MISSION

Our mission is to strengthen the Vietnamese medical herb industry by fostering a vibrant business community.

Use cutting-edge scientific and technological innovations to develop high-quality products that help to protect and improve public health.

Increase the value of Vietnamese medicinal herbs and introduce healthcare products into the global market.

FIELD OF ACTIVITY

Formulation of functional food formulations

With experience and a team of highly qualified personnel, we support partners: consulting, formulating functional food formulations to ensure safety, maximum cost savings, and outstanding efficiency.

Register for publication of food safety conformity

As one of the professional enterprises in the preparation and production of nutritional foods, functional foods, with a team of professional staff who understand the regulations and processes, we are confident to help our partners register the food safety compliance, support perfect services for partners.

Pharmaceutical production – functional foods

Life Gift Vietnam has many years in the prestigious functional food manufacturing industry with a team of highly qualified personnel, modern production lines meeting the strict standards of the Ministry of Health, we are confident to be a trusted manufacturer. Reliable for pharmaceutical business partners with perfect service, maximum support when processing at the Factory.

HISTORY OF FORMATION & DEVELOPMENT

- 2017 – 2018:

-

- Market research survey

- Building a factory

- Business registration

- HR Recruitment

- 2019 – 2020:

- Factory completed and put into operation

- Receiving and cooperating in the transfer of production technology from abroad (Malaysia, Singapore, China..)

- Owning and protecting the brand Wellness by Life Gift Vietnam

- In May 2020: achieved ISO 22000: 2018 Quality Management System certification

- In June 2020: GMP standard (Vietnam has 140 factories certified by the Ministry of Health of Vietnam)

- Producing, processing and launching health protection products/supplements

- 2021 – 2022:

- Continuous development

- Party and government leaders of Vietnam regularly visit

- Cooperation in technology transfer between Life Gift VN and Faculty ofPharmacy – Nguyen Tat Thanh University

- Obtained US FDA certification

- 2023 – 2024:

- Continue to manufacture and trade ODM/OEM products

- Researching and preparing formulas of healthy food

- 2024 – 2025:

- Collaborate with 100+ commercial and manufacturing partners for ODM/OEM

- Increase product exports to overseas markets, particularly Southeast Asia and Europe.

- Use cutting-edge technology in production, research, and product formulation.

- Collaborate with research institutes to create innovative healthcare products.

- 2025 – 2030

- Lead the manufacture of health-protecting supplements in Vietnam.

- Enhance production scale, competitiveness, and international market position.

- Develop Vietnam’s medicinal herb sector, boost domestic resource value, and meet global standards.

The factory is equipped with many modern production lines

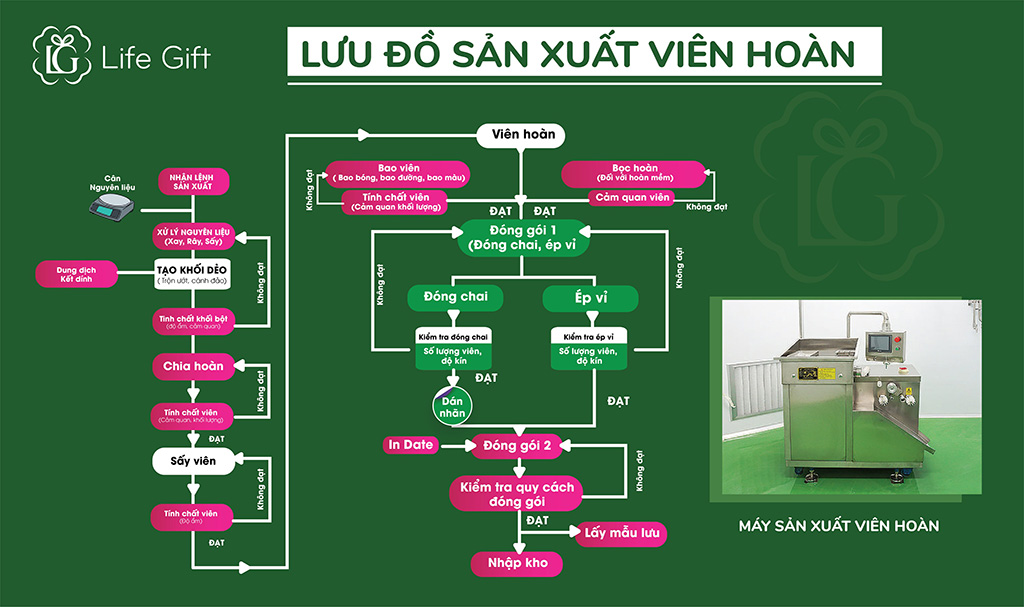

Complete pellet production line

The complete tablet production line is an automatic system for the production of drugs in the pharmaceutical industry. In fact, this system includes many different types of machines, so the production process is quite complicated. Therefore, to create a perfect product that meets the requirements, the operator must possess specialized techniques and high skills.

The complete tablet production line is most commonly used in the field of medicine. When it comes to complete pills, you will probably immediately think of Northern and Southern pills. But now, the form of complete tablets is still widely used, and increasingly popular.

FOOD POWER SPECIFICATIONS

Productivity: 150 kg/shift

Specification: Mold 8.5 mm

3 shifts/day: 450 kg

Output/year: ~ 162 Tons

* Note : Depends on pellet diameter.

Capsule production line

Hard capsules absorb water very well and dissolve quickly in the body. Hard capsules are usually used to contain the active ingredients in the form of powder or crushed nuggets. To prepare this capsule requires a modern and advanced production line. Not only meet the production, but the line must operate at the best efficiency. As a result, the cost of the product will be kept to a minimum.

FOOD POWER SPECIFICATIONS

Productivity: 250,000 tablets/shift

Specification: Capsule No. 0

3 shifts/day: 400 kg

Output/year: ~ 144 Tons

* Note : Capsules 500 mg

Blister pressing production line

The laminating line is a set of pre-set operations that can produce a finished product. However, these operations are not performed on one but many different machines. As a result, the finished product is perfect and uniform in both size and weight.

FOOD POWER SPECIFICATIONS

Productivity: 300,000 tablets/shift

Specification: Mold of 4 blisters Blister of 10 tablets

3 shifts/day: 1 million tablets

Output/year: ~ 360 million tablets

* Note: Depends on the number of pellets on the span/mold

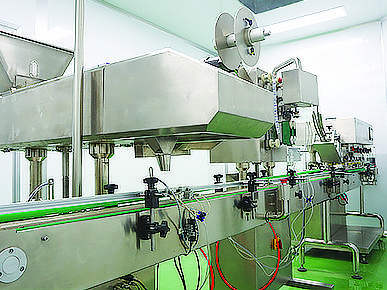

Bottle packing line

This is an automatic line consisting of many devices that are connected to each other according to a certain process. Thanks to the production line, people do not need to spend too much time and effort but still ensure the highest level of performance. Currently, this line is completely closed by the most advanced modern machines.

FOOD POWER SPECIFICATIONS

Productivity: 9000 Bottles/ca

Specification: Bottle of 100 tablets

3 shifts/day: 30,000 bottles

Output/year: ~ 10.8 million bottles

* Note: Depends on the number of tablets in the bottle

Tablet stamping production line

Tablet production line is the process of preparing health food or solid medicine. This process will be made by compressing one or more substances together into a flat cylinder, oval or round shape. Usually, the product will have 2 types: bare tablets and film-coated tablets.

FOOD POWER SPECIFICATIONS

Productivity: 250,000 tablets/shift

Specification: Run 3 shifts/day: 400 Kg

Output/year: ~ 144 Tons

* Notes: 500 mg tablets

Packing machine line

This is an automatic packaging machine line designed to squeeze packages for medicinal products, pharmaceutical products in powder form, nuggets…

The line is manufactured according to the most advanced standards and techniques in accordance with the requirements of GMP – ISO 22000:2018

FOOD POWER SPECIFICATIONS

Productivity: 12,600 packs/shift

3 shifts/day: 300 Kg

Output/year: ~ 108 Tons

* Note: Pack of 10g

Film-coated tablet – tablet production line

The tablets and capsules will be film-coated through extremely complex operations. Therefore, it is not easy to do this work. By the production line of sugar coating, color coating and polishing combination for tablets and finished tablets. This process has a huge influence on the final quality of the product.

FOOD POWER SPECIFICATIONS

Output/year: ~ 50 Tons

The production room is built according to d clean standards

PRODUCTION AREA

The production area is divided into 4 subdivisions including production lines:

- Solid line includes: Tablets, film-coated tablets, sugar-coated tablets, hard capsules, powders, hard capsules, soft capsules.

- Packing area level 2 Above there is a technical floor to install an air conditioning system.

- The production area is designed according to a one-way process with separate paths for people, materials, and packaging.

- The factory produces concrete frames, outer walls, ceilings, panels combined with glass, ceiling walls and paints with smooth, waterproof, easy-to-clean and dust-free surfaces.

- The corners and edges between the floor, wall and ceiling are rounded, without burrs to ensure hygiene.

TEST ROOM

The testing area is located far from the production workshop, Total area: 110 m2 including the main areas are:

- Physicochemical area

- Microbiological area

- The Regional Office stores samples, studies the stability.

The physicochemical testing zone includes:

Central physicochemical testing room, chemical cabinet, fume hood, instrument washing area, weighing room, machine room and heat generating equipment room.

The microbiological testing area consists of a clean grade A culture in a clean grade D infection test room.

Environment preparation room, incubation room, changing area into clean room D.

TESTING EQUIPMENT

The company develops an annual calibration plan of analytical equipment, all machines are stamped with calibration stamps.

The company has equipped with chemicals, standard substances, some strains of microorganisms for quality control and food safety according to regulations.

The quality control department has established a system of records and documents including procedures, instructions, and references to documents such as TCVN, Vietnam Pharmacopoeia V, USP 41.

22 types of laboratory equipment:

1. 4 NUMBER ANALYSIS BALANCE

2. ELECTRONIC WEIGHT

3. ENVIRONMENTAL STORAGE Fridge, Microbial Strain

4. LEVEL 2 BIO SAFETY SHOCKET

5. INTRODUCTION, COOLER

6. FEATURES FEATURES

7. PROVINCIAL DRYER

8. MEASUREMENTS

9. CONDUCTIVE MEASUREMENTS

10. WATER WATER KITCHEN 4 LOCATIONS

11. 2 POSITION LENSITY Meter

12. WHITE STEAM OIL

13. BIOLOGICAL MICROSCOPE

14. MICROFILTERS VACUUM PUMP ROCKER 300

15. HEAT MAGNETIC STRUCTURE

16. 1200 KILLING Oven

17. BASE-free desiccator 240

18. SPRAY GENERAL CHARACTERISTICS

19. DISCLOSURE DEVELOPMENT

20. CHARACTERISTICS

21. COVERAGE DIFFERENT SET

22. ESSENTIAL OIL dosing kit

Production equipment

Weighing and roasting ingredients

ELECTRONIC WEIGHT 15 Kg

ELECTRONIC WEIGHT 3 Kg

TECHNICAL WEIGHT 600 g

AUTOMATIC FILTERING MACHINE

Solid pellet production line

AUTOMATIC CAPSUAL MACHINE

SELL AUTOMATIC CAPSUAL MACHINE

AUTOMATIC DRAWING MACHINE

PROVINCIAL DRYER

DRAWING MACHINE

TOWER TYPE MIXING MACHINE

AUTOMATIC BLOLDING MACHINE FILM SACKING MACHINE,

POWDER PACKING MACHINE

MASTIC COOKING SYSTEM

BOILING MACHINE

TABLET COUNTER

Dehumidifying bag removal machine

BOILING MACHINE ONLY

Level 2 packaging equipment and other equipment

LABELING MACHINES

COLORING MACHINE

CUTTING MACHINE

THERMAL HYGROMETER

DIFFERENT VOLTAGE TIMER DEVICES DIGITAL WEIGHT PRODUCTION ZONE 2

HARDWARE TESTING MACHINE

QUICK DRYING WEIGHT

Abrasion TESTING MACHINE

TESTING MACHINE