PRODUCTION CAPACITY – LIFE GIFT VIETNAM FACTORY

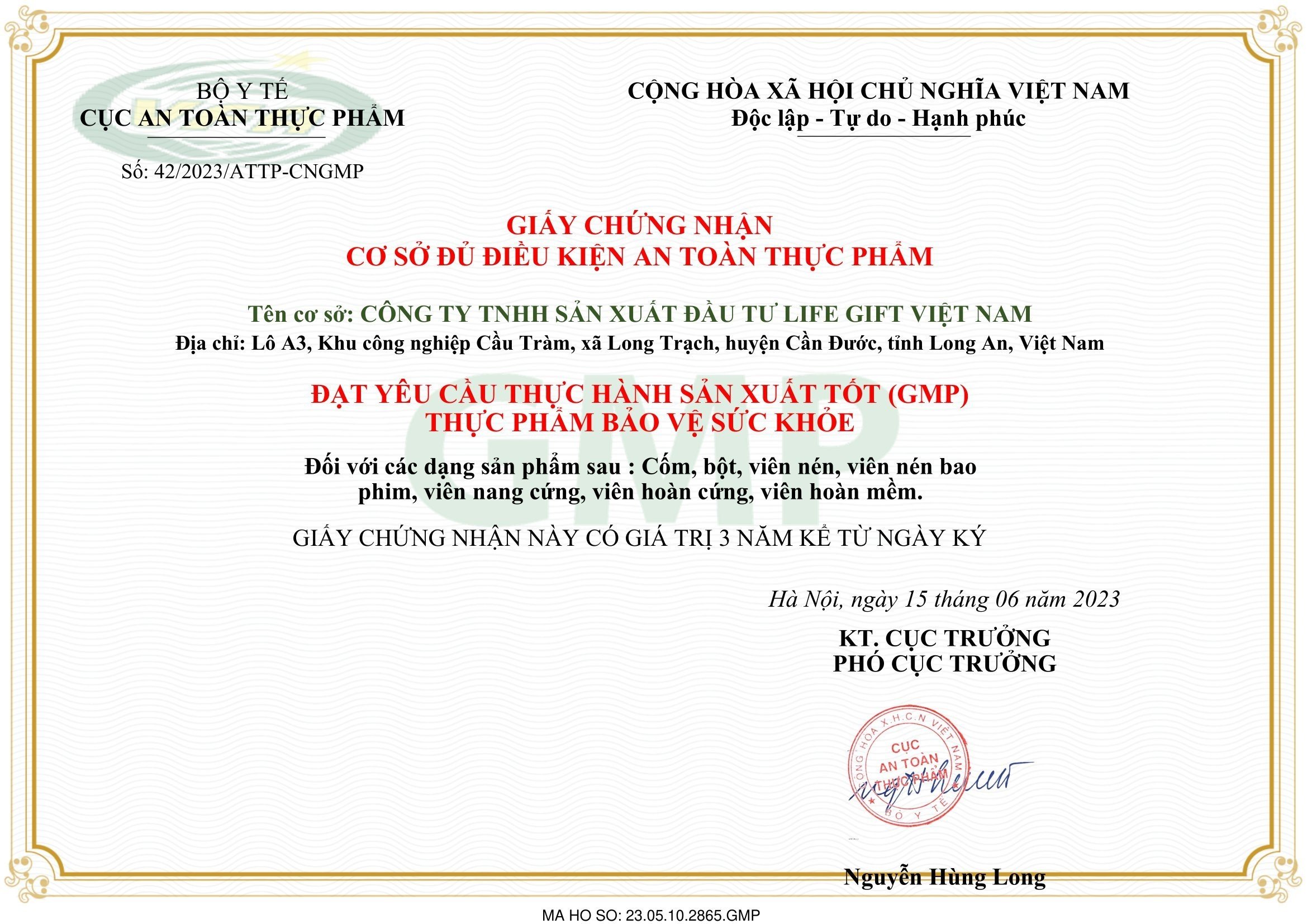

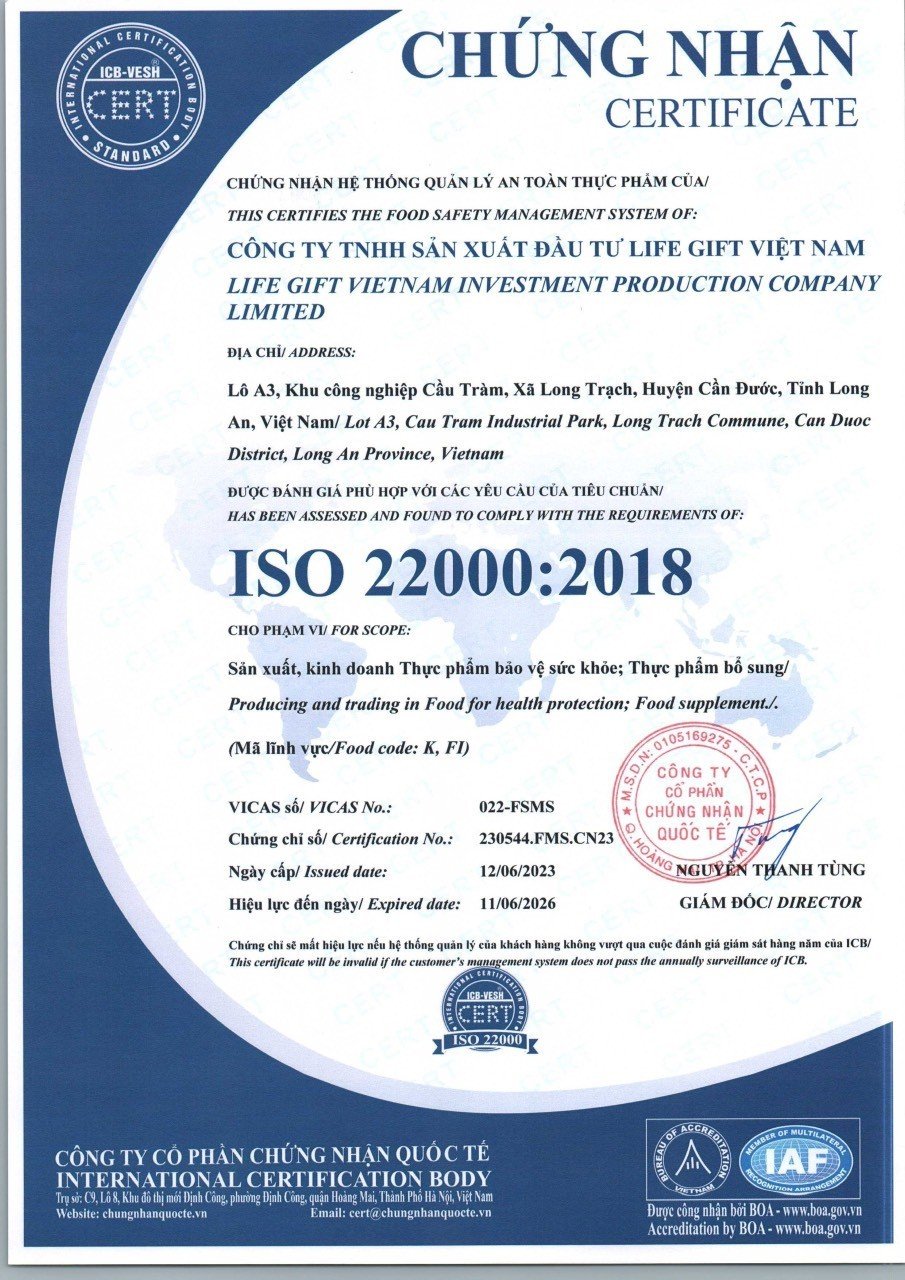

Life Gift Vietnam factory is built according to GMP – ISO 22000:2018 standards, with a modern production line system, closed operation and one-way production process. The factory is capable of producing a variety of dosage forms: pills, capsules, tablets, powders, granules, packages, ready-to-drink bottles… serving the production of functional foods according to high quality standards.

The production area is designed to meet clean standards level D, with smooth walls and ceilings, easy to clean, and dust-free. The air conditioning system, pressure control and material and human circulation are arranged reasonably according to a one-way process.

TESTING ROOM – TOP QUALITY

The testing room meets the standards with a total area of 110 m², including a physical-chemical area, a microbiological area and a sample storage area. Fully equipped with modern analytical and measuring equipment, periodically calibrated and operated according to standard document systems such as Vietnam Pharmacopoeia, USP 41, TCVN.

Some outstanding equipment:

Analytical balance, pH meter, disintegration tester, level 2 biological safety cabinet, fume hood, biological microscope, autoclave, hardness tester, abrasion tester, rapid moisture balance, etc.

MODERN PRODUCTION EQUIPMENT

The production and packaging machinery system is invested synchronously, including:

- Automatic & semi-automatic capsule filling machine.

- Blister press, tablet press, film coating machine.

- Raw material mixer, malt cooker.

- Tablet counting, capping, labeling, shrink wrapping machine.

- Other equipment supporting quality control and secondary packaging.